Plasma is the most

environmentally safe method of both organic removal and surface

modification to date. Plasma processes can be tailored to produce

hydrophobic or hydrophilic surfaces on metals, plastics, glass or

polymers. Recent advances in the uses of polymers and as a result

the need for hydrophilic surfaces for adhesion has fueled the

development of the plasma surface modification industry. This

seminar will review the current industry and how it addresses the

adhesion issue in terms of available equipment and future

potential.

What is Plasma

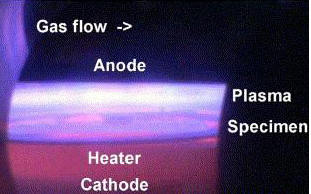

Plasma can loosely be

defined as a partially or wholly ionized gas with a roughly equal

number of positively and negatively charged particles. It has been

dubbed as the “fourth state of matter" because of its general

properties which are similar to both a gas and a liquid.

There are both high and

low temperature plasmas. High temperature plasma is found at

atmosphere in its manmade form as a plasma torch or naturally in

the form of lightning,.Low temperature plasmas, as used in surface

modification and organic cleaning, are ionized gases generated at

low pressures. These low pressures allow for a relatively long

free path of accelerated electrons and ions which are essentially

at ambient temperatures. With relatively few collisions there is a

low energy transfer thus keeping the temperature of the reaction

in the ambient range.

The ionization of the

gas is accomplished by applying an energy field using one of three

government regulated

source frequencies:

Low frequency or < 100 KHZ.

RF frequency or 13.56 MHZ.

Microwave frequency or 2.45 GHZ.

The frequencies selected

for these sources are controlled by international agreements to

prevent use of sources which would interfere with communication

bands worldwide. Unfortunately for manufacturers, the least

desirable method of generation is

also the least expensive - low

frequency. Low frequency plasmas are the least eflicient

for several

reasons which go beyond the scope of this presentation. The efficiency

is related to the energy necessary to sustain the ionization and

both the intensity and frequency of vacuum ultraviolet (VUV)

radiation.

Most plasma system

use either RF frequency or MW frequency sources.

XBH uses almost exclusively RF sources because of the overall

advantages associated with this

method. RF plasmas have been shown to exhibit significantly higher

levels of VUV which in part explains the higher concentrations of

electronically charged particles than found in the other plasma

sources. RF plasmas have also been noted to be more homogeneous

which is critical in treating irregularly shaped and overly large

objects.

MW source plasmas are

generated “downstream” or in a secondary environment. This means

that the plasma is generated in one chamber and the active species

are drawn by vacuum differential into the work area. Though this

can be advantageous for organic removal it does produce a less

homogeneous process and as a result provides reduced uniformity

across the work area. In areas of surface modification the

effective depth of the modification is tens of nanometers so the

uniformity of the process becomes increasingly important.

There are several

resultant effects to the plasma interaction with the surface, each

of which has a reaction to the adhesion process. These effects

are, but are not restricted to:

Organic removal

CASING (Crosslinking via Activated Species of Inert Gases)

Ablation

Surface chemical restructuring