|

One of the biggest hurdles

to the widespread adoption of optical backplanes is the need for

an economic process to manufacture optical waveguides in

backplanes up to 1 m in size. Groups in Japan, Europe and N.

America have been investigating a number of techniques for

fabricating optical waveguides embedded within conventional

PCBs. PPC/Isola use silica as their optical waveguide which has

the benefit of very low loss, but is difficult to fabricate.

STET use polymer, and emboss the waveguides. It is difficult to

achieve good surface finish using this process, and the

resultant guides can have high losses.

BPA identify polymer as

being attractive for a number of reasons including its intrinsic

low cost and scalability. BPA highlight concerns of as high loss

(0.1 – 0.6 dB/cm) and insufficiently resistant to lamination and

reflow processes used in PCB manufacture. Terahertz Photonics

set out to develop its photosensitive TRUEMODE TM polymer

to simultaneously meet these requirements.

The resultant TRUEMODE

BackplaneTM

polymer has:

• Optical loss of < 0.04 dB/cm at 850

nm

• A high glass transition temperature

of 150°C.

• A high degradation temperature of 350 °C

Terahertz Photonics come

to the optical backplane world with a growing heritage in

polymer optical components. Variants of the TRUEMODETM family of

polymers are finding application in components including

splitters and fan-outs. Expertise obtained in the tight

fabrication tolerances and polymer requirements for these single

mode components fed naturally into the development of TRUEMODETM

polymer for optical backplanes.

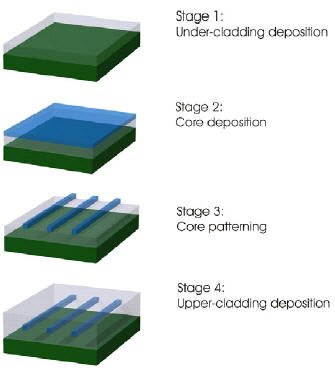

The process by which the

optical medium is deposited 0on the substrate and patterned to

form waveguides is central to optical backplanes. The process

consists of four stages. See figure

3.

Figure 3: TRUEMODE

BackplaneTM

process

The first

stage consists of deposition of monomers in a ~20 μm

thick undercladding using screen printing followed by low

intensity UV polymerisation.

The second

stage consists of the deposition of a 50 μm

thick layer of monomers having a refractive index typically 1%

higher than the cladding.

In the third

stage the polymer is patterned by photolithography or laser

direct write using a low power UV laser such as a He:Cd laser

[2].

The final

stage is a repeat of the first, though the layer thickness may

be increased for greater protection of the core.

If you don't find what you're looking for,

Contact Us.

We may have a suitable product that's not listed, or we may be

able to develop a material to fit your specific needs.

Tel : (02)2217-3442 / Fax : (02)2704-4070

|

|